SMC Compression Molding - SMC compression molding is unique way of making wide range of items using particular kind material known as Sheet Moding Compound i.e. in short form leading with SMC These are small pieces of fiber; a form or two: the plastic that is not part of these elements and some others materials combined. With this blending capacity SMC service tends to be a very strong and durable material suite for any product manufacturing.

SMC compression molding offers several benefits where product manufacturing is concerned. It is advantageous because it can make many types of shapes or designs. Considering the flexibility of SMC it is readily molded into required shapes. As a result, manufacturers are able to produce items that have not only high strength but also lightweight nature. This type of product is also good in terms of ease and convenience as products with the SMC can be lifted easily simply by your hand.

Saving money is another perk of SMC compression molding. Plastics such as SMC are typically more cost-effective than higher-cost materials like metal for most manufacturing applications. For businesses, a reduction in production costs is good for business as this could be cost-effective. SUSTO Compression molding for SMC is environmentally-friendly as well. This reduces waste and energy use for making a more sustainable choice over some other manufacturing methods.

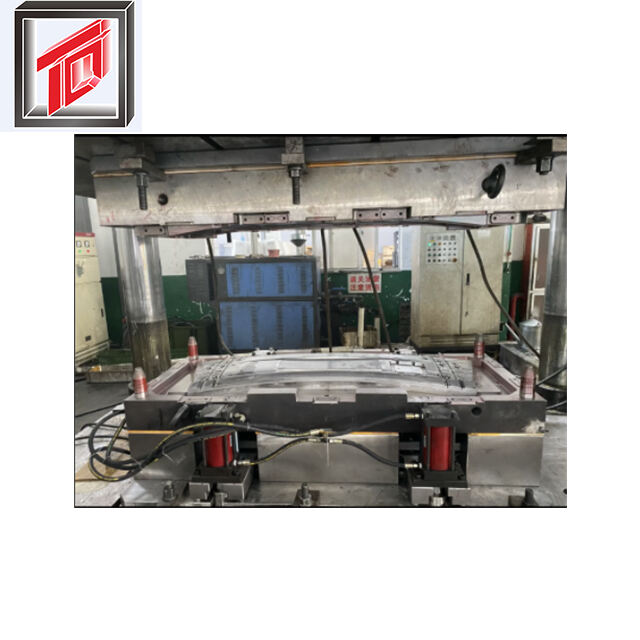

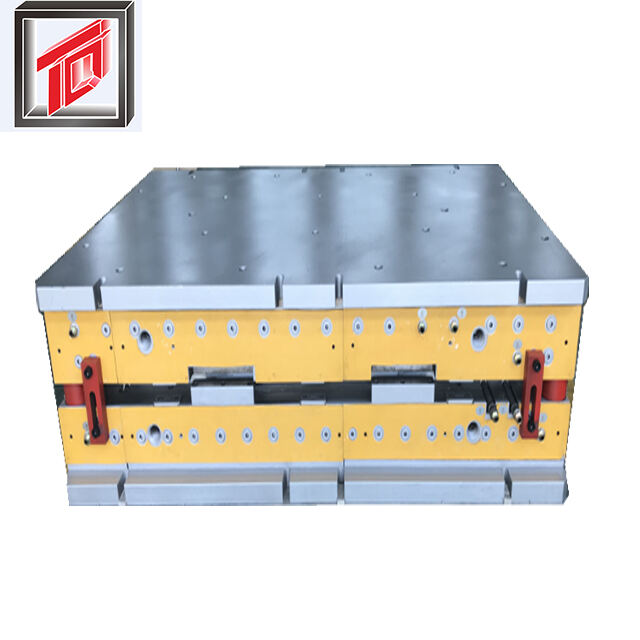

Well what is SMC compression molding actually'])) THE FIRST STEP is to take a weighed amount of SMC and insert it into a mold, which forms the part. The mold is then closed, and the SMC will sit in it at high temperature. The SMC is a liquid when it gets hot. The liquid mould then is filled up and conform to the shape of it.

The application of SMC compression molding is very extensive. It is used in many products including car parts and small home appliances. SMC is strong and flexible so it performs well in high-wear parts as well as tight tolerance applications. Typical applications for products manufactured with SMC compression molding include car bumpers, different parts of industrial machines and even shower stalls or some musical instruments.

When it comes to creating products, SMC compression molding is just one of several methods manufacturers may use. There are multiple benefits and limitations to each method of manufacturing. The optimal choice often comes down to the particular product that is being created and its specifications.

Compared to many other methods of manufacturing, SMC compression molding is also often quite economical. It wastes less and consumes fewer resources. Moreover, this method allows you to print intricate shapes and designs. Note, SMC compression molding is not ideal for all types of products. Others may require a higher level of detail or strength that can be difficult to achieve, depending on the method used.