Home / Products / Moulds / Thermosetting mould / SMC mould

TQ’s good selling compression resin mold smc auto fairing mould is the perfect solution in the production of durable automobile fairing elements. This fantastic item was made to meet with the requirements of automotive manufacturers and fix stores that are looking to meet the growing popularity of well-designed automobile components.

The Compression good selling compression resin mold smc auto fairing mould was manufactured with top-quality materials. The mold comprises of Sheet Molding Compound (SMC) product and resin, which is known to their superior energy. This makes the mold well suited to making of car fairing components that can withstand the rigors of regular usage, including exposure to harsh climate conditions and effects.

The TQ good selling compression resin mold smc auto fairing mould was made for simplicity along with its high durability. It provides an easy and intuitive design that enables simple procedure and upkeep. The mold is also versatile and can be used to develop a wide variety of components, including bumpers, grilles, spoilers, and fenders.

The TQ good selling compression resin mold smc auto fairing mould was made to satisfy the requirements of automotive manufacturers and it was built with a number of enhanced functions. The mold includes a superior heating that guarantees constant and accurate heat control through the molding task. It can help to prevent the possibility of defects and inconsistencies to the final item.

The TQ good selling compression resin mold smc auto fairing mould was constructed with high rate monitoring and diagnostic tools that allow operators to keep tabs on the molding procedure while making real-time changes as required. This particular feature ensures that this product can complete the requirements with no need for time-consuming rework or high priced rejections

Taizhou Tianqin Mould & Plastics Co., Ltd

good selling compression resin mold smc auto fairing mould

A professional mould maker

We're specialized in making

plastic compression mold (FRP mold, SMC mold, BMC mold, DMC mold) and plastic injection mold PP, ABS, PC, PA6/PA66 materials

We usually sell

SMC meter box mold

SMC bumper mold

SMC lamp mold

FRP manhole cover mold

SMC meter box mold

SMC bumper mold

SMC lamp mold

plastic trash mold

plastic tray mold

SMC door skin mold

plastic household mold

BMC auto parts mould

SMC BMC Ceiling Mould

Information for your reference:

|

Name |

Description |

|

Mould materials |

45#, 50#, P20, H13, SKD61, etc |

|

Cavity |

Single/Multi |

|

Runner |

/ |

|

Design software |

UG, CAD, PORE, etc |

|

Mould life |

100,000-1,000,000shots |

|

Delivery time |

35-45 days |

|

Specification |

According to client's requirements |

Steps:

|

1. R&D |

We support customer R&D. Design or improve design for you |

|

|

|

|

2. Quotation |

Within 24 hours |

|

|

|

|

3. Order |

Use your own design or use ours. We will send schedule to you as soon as we receive your confirmation |

|

|

|

|

4. Mould |

All parts will be produced according to the design. Build the mould according to your request, send mould design to you for approval before processing, send sample to you before product manufacturing |

|

|

|

|

5. Sample shoot |

If you are not satisfied with the first sample, we will modify the mould until it meets your requests |

|

|

|

|

6. Products in store |

If your quantity is beyond our storage, we'll provide lead time |

|

|

|

|

7. Delivery |

By sea or by air, according to your requirements |

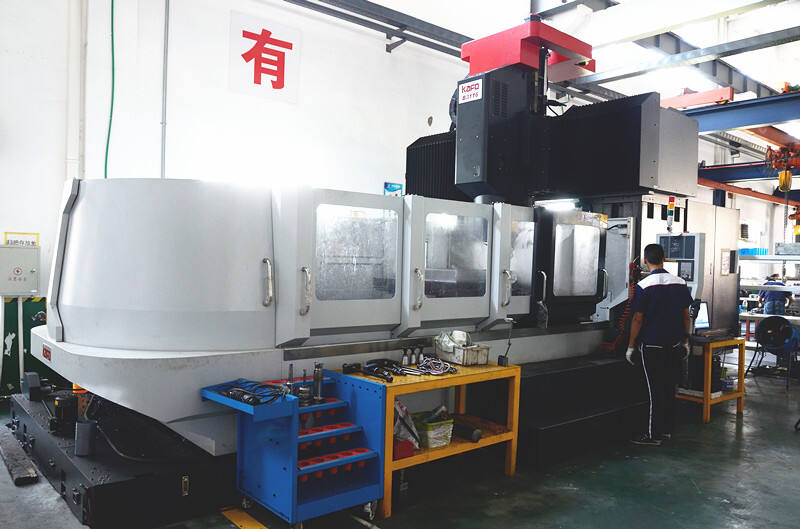

OUR FACTORY

Our professional sales team is always waiting for your consultation.