Introducing, the TQ Pasgt composite compression helmet mould, a durable and dependable item developed to provide maximum protection high-risk operations. This product was made of premium-quality materials and was expertly-engineered to withstand the rigors of tough conditions.

Crafted with quality and durability in mind, the TQ Pasgt composite compression helmet mould was built to meet the best industry demands. It is lightweight yet provides excellent power to make sure users are well-protected in dangerous environments. The helmet comes with an outer part that was made of tough composite materials which can withstand strong impacts, along with an interior liner to take in shock and lower the chance of brain accidents.

One of the top features of this helmet mould is the superior compression included in its design. This particular feature ensures that the helmet remain on the person's head while providing superior safety during fast and powerful motions. The helmet's interior liner was crafted to produce venting that will keep the user cool and comfortable throughout extended durations of use.

The TQ Pasgt composite compression helmet mould is incredibly versatile and thus can be used in a number of settings, including military operations, combat, authorities, and various high-risk environments. It was made to offer different compatibility including systems, head-mounted programs, and night vision devices.

The TQ Pasgt composite compression helmet mould provides both functionality and design featuring its sleek and modern design. It truly is available in a number of colors to complement alternatives and can easily be modified to suit different sizes

Taizhou Tianqin Mould & Plastics Co., Ltd

pasgt composite compression helmet mould

A professional mould maker

We're specialized in making

plastic compression mold ( FRP mold, SMC mold, BMC mold, DMC mold) and plastic injection mold PP, ABS, PC, PA6/PA66 materials

We usually sell

SMC meter box mold

SMC bumper mold

SMC lamp mold

FRP manhole cover mold

SMC meter box mold

SMC bumper mold

SMC lamp mold

plastic trash mold

plastic tray mold

SMC door skin mold

plastic household mold

BMC auto parts mould

SMC BMC Ceiling Mould

Information for your reference:

|

Name |

Description |

|

Mould materials |

45#, 50#, P20, H13, SKD61, etc |

|

Cavity |

Single/Multi |

|

Runner |

/ |

|

Design software |

UG, CAD, PORE, etc |

|

Mould life |

100,000-1,000,000shots |

|

Delivery time |

35-45 days |

|

Specification |

According to client's requirements |

Steps:

|

1. R&D |

We support customer R&D. Design or improve design for you |

|

|

|

|

2. Quotation |

Within 24 hours |

|

|

|

|

3. Order |

Use your own design or use ours. We will send schedule to you as soon as we receive your confirmation |

|

|

|

|

4. Mould |

All parts will be produced according to the design. Build the mould according to your request, send mould design to you for approval before processing, send sample to you before product manufacturing |

|

|

|

|

5. Sample shoot |

If you are not satisfied with the first sample, we will modify the mould until it meets your requests |

|

|

|

|

6. Products in store |

If your quantity is beyond our storage, we'll provide lead time |

|

|

|

|

7. Delivery |

By sea or by air, according to your requirements |

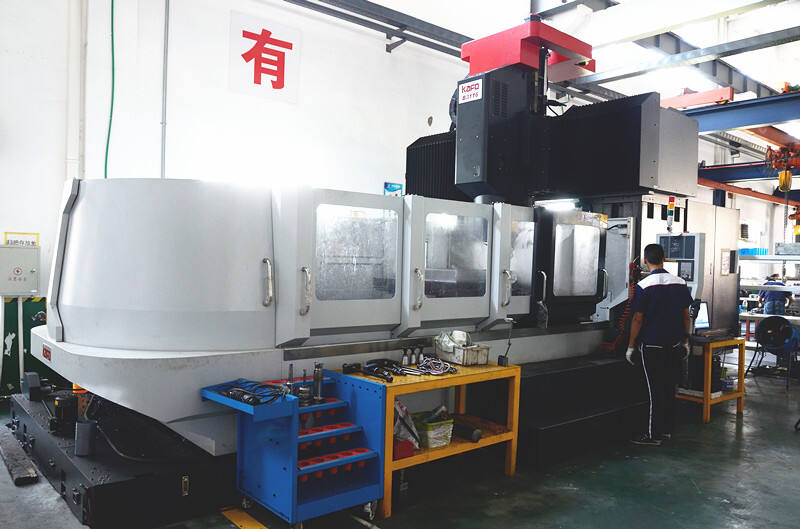

OUR FACTORY

Our professional sales team is always waiting for your consultation.