TQ

Launching the zhejiang taizhou SMC BMC compression press modern die Stamping Die Tooling for automobile components, proudly presented- your brand name trusted for tooling solutions.

This method is built to effectively and effectively produce high-precision automobile parts for different makes and models. The SMC BMC compression press provides a process structured produces consistent components quicker, without having to sacrifice quality and precision.

The die that is modern Die Tooling permits the development of complex forms and designs, providing to your growing interest in custom automobile components. Using this tooling that is particular you are going to create components being numerous one swing, causing paid off material waste and production expenses.

Manufactured with high-grade materials, this tooling was made to withstand force that is warm, ensuring durability and dependability for a long period in the foreseeable future. The trend that is robust minimizes downtime and repairs, doing your best with your efficiency and earnings.

The zhejiang taizhou SMC BMC compression press modern die Stamping Die Tooling for automobile components can be user-friendly, insurance firms a screen easy intuitive setting. This may ensure it is simple for your group to focus and maintain the tooling, reducing the possibility for mistakes and accidents.

This tooling normally eco-friendly, having a paid down carbon impact and minimal waste generation as well as the exemplary performance. This aligns with TQ's commitment to production and sustainability accountable.

With this proven history of delivering innovative and tooling top-quality, TQ is specialized in fulfilling the diverse requirements of car manufacturers and companies. Our approach means that are customer-centric have the help and guidance had a need to optimize your manufacturing procedure and reach finally your company objectives.

Taizhou Tianqin Mould & Plastics Co., Ltd

zhejiang taizhou SMC BMC compression press progressive die Stamping Die Tooling for auto parts tooling

We're specialized in making

thermosetting plastic compression mold

(FRP/GRP mold, SMC mold, BMC/DMC mold)

plastic injection mold (PP, ABS, PC, PA6 material, etc.

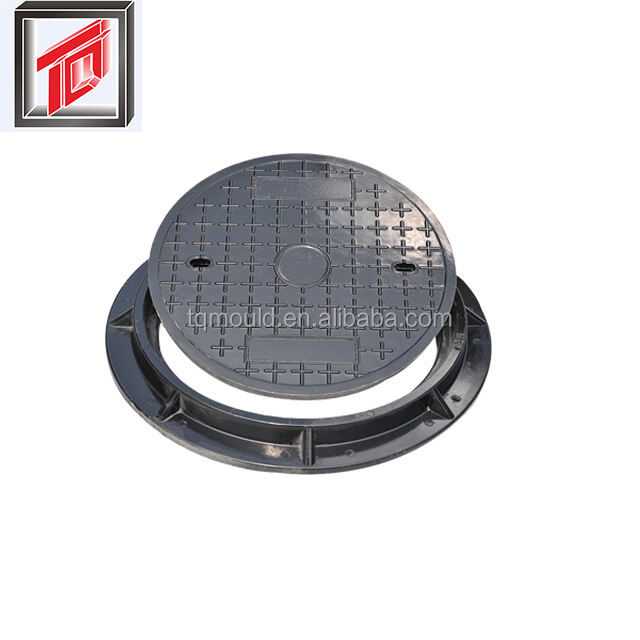

FRP manhole cover mold

SMC meter box mold

SMC bumper mold

SMC lamp mold

plastic trash mold

plastic tray mold

SMC door skin mold

plastic household mold

M88 helmet mold

SMC water tank mold

FAST PASGT MICH PE helmet mould

Helmet mould

Name |

Description |

Mould materials |

45#, 50#, P20, H13, S136, SKD61, etc. |

Cavity |

Single/Multi |

Runner |

cold/hot |

Design software |

UG, CAD, PORE, etc |

Mould life |

100, 000-1, 000, 000shots |

Delivery time |

35-50 days |

Specification |

According to client's requirements |

1) Provide various kinds of Bulletproof helmet mould according to your requirements.

2) We own advanced CAD/CAM/CAE/systems and large processing detection

equipment, such as imported hight-speed milling, MAKINO, DMG high-speed milling, CNC machining Center, MAKINO sparks, WEDM-LS cutting machine, clapper die spotting press, etc. We also have

established a CAD/CAM/CAE mould design and development center.

3) Good quality, competitive price and efficient service

1. R&D |

We support cutomer R&D. Design or improve design for you. |

|

|

2. Quotation |

Within 24 hours |

|

|

3. Order |

Use your own design or use ours. We will send schedule to you as soon as we receive your confirmation. |

|

|

4. Mould |

All parts will be produced according to the design. Build the mould according to your request, send mould design to you for approval before processing, send sample to you before product manufacturing. |

|

|

5. Sample shoot |

If you are not satisfied with the first sample, we will modify the mould until it meets your requests. |

|

|

6. Products in store |

If your quantity is beyond our storage, we'll provide lead time. |

|

|

7. Delivery |

By sea or by air, according to your requirements. |

FACTORY VIEW

Our professional sales team is always waiting for your consultation.