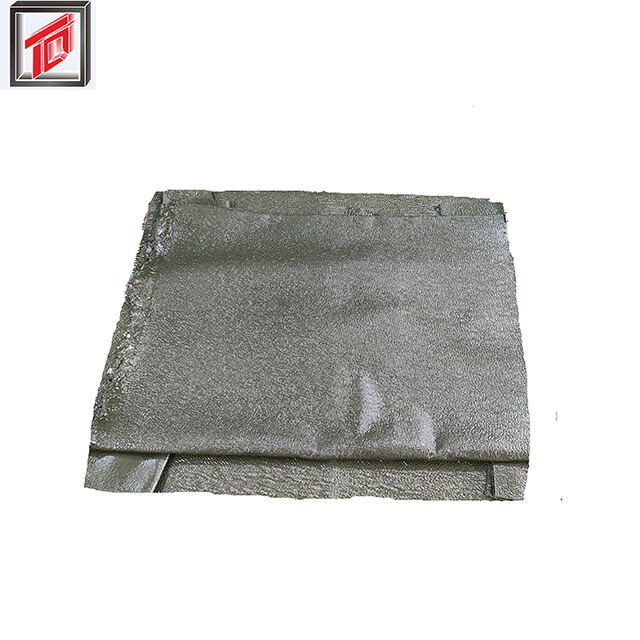

SMC production process

SMC (Sheet Molding Compound) molding process is an advanced composite molding technology, which is mainly used to produce high-performance composite parts. The process involves prefabricated sheet molding compounds, the main components of which include unsaturated polyester resins, glass fibers, fillers, thickeners, initiators, crosslinkers, and other additives. The following is an overview of the technical characteristics of the SMC molding process and its application progress in recent years:

Technical features:

1. Premix and preform: SMC forms a sheet-like semi-finished product with a certain thickness by pre-mixing resins and other reinforcing materials, which is convenient for storage and transportation.

2. Precise control: Since the composition and thickness of the SMC material can be precisely controlled, the quality and consistency of the final product can be guaranteed, and it is not affected by the operator's skill or environmental conditions.

3. Efficient molding: The SMC sheet is placed into the preheated mold, and the hydraulic press is used to apply pressure and temperature to melt it and fill the mold cavity, and then go through the pressure holding and curing stages to form the required complex geometry of the parts.

4. High performance: SMC products have high mechanical strength, corrosion resistance, good electrical insulation properties and lightweight characteristics, and are suitable for structural and functional parts in automobile, electric power, construction, rail transit and other industries.

Application Progress:

Automotive industry: With the increasingly stringent environmental regulations and improved fuel efficiency requirements, the automotive manufacturing industry has adopted SMC materials to replace traditional metal parts, such as body panels, battery boxes, hoods, bumpers, etc.

New energy field: In the electric vehicle (EV) market, SMC is used to make battery pack shells, charging pile shells, etc., providing good insulation and protection performance.

Infrastructure: In the utility and construction industries, SMC is used in the manufacture of lightning protection equipment, cable supports, water tanks, manhole covers, and more, and is favored for its durability and cost-effectiveness.

Aerospace & Defense: Although the application of SMC in the aerospace field is relatively limited, its lightweight and high strength characteristics make it have some room for development in some sub-structural parts and interior parts.

Other fields: With the continuous improvement and optimization of SMC material formulation, its application fields are also expanding, such as sports equipment, home appliance shells, etc.

In general, with its unique technology and advantages, the SMC molding process is developing in the direction of a wider and more high-end application, especially in the field of automotive lightweight and new energy. At the same time, with the continuous innovation of composite technology, SMC's position in the future high-performance composite market will be more solid.