-

With over 15 years OEM & ODM experience, TQ Mould Co.,Ltd. Is a professional manufacturer and exporter in zhejiang Taizhou Huangyan, We export not only abroad but also domestically. Specialized in designing and manufacturing high-quality plastic injection mould. More than 25 sets of equipment for mould processing, manufacturing, trial and parts production. Including Milling Machine,Cutting Machine,CNC Machine,EDM Machine, Grinder Machine,Drilling Machine,Hydraulic Press Machine.ect.We can also provide 3D design,mold making and bulk production service for your company!

Main Compression and Injection Mould Category:

- 1. Auto parts mould: heavy-duty truck bumper, instruments panel, car roof, door panel, trunk cover, sky shade, engine hood, air conditioner shell, battery box, etc.

- 2. Kitchenware & sanitary ware mould: bathtub, shower room, shower tray, waterproof plate, toilet lid, sink, table top, melamine tableware, etc.

- 3. Electronic appliance mould: electric switch box, power distribution box, electric fan cover, meter box, cable branch box, cable holder, insulator, insulating cover, etc.

- 4. Sports equipment mould: basketball board, table-tennis table board, FRP chair, etc.

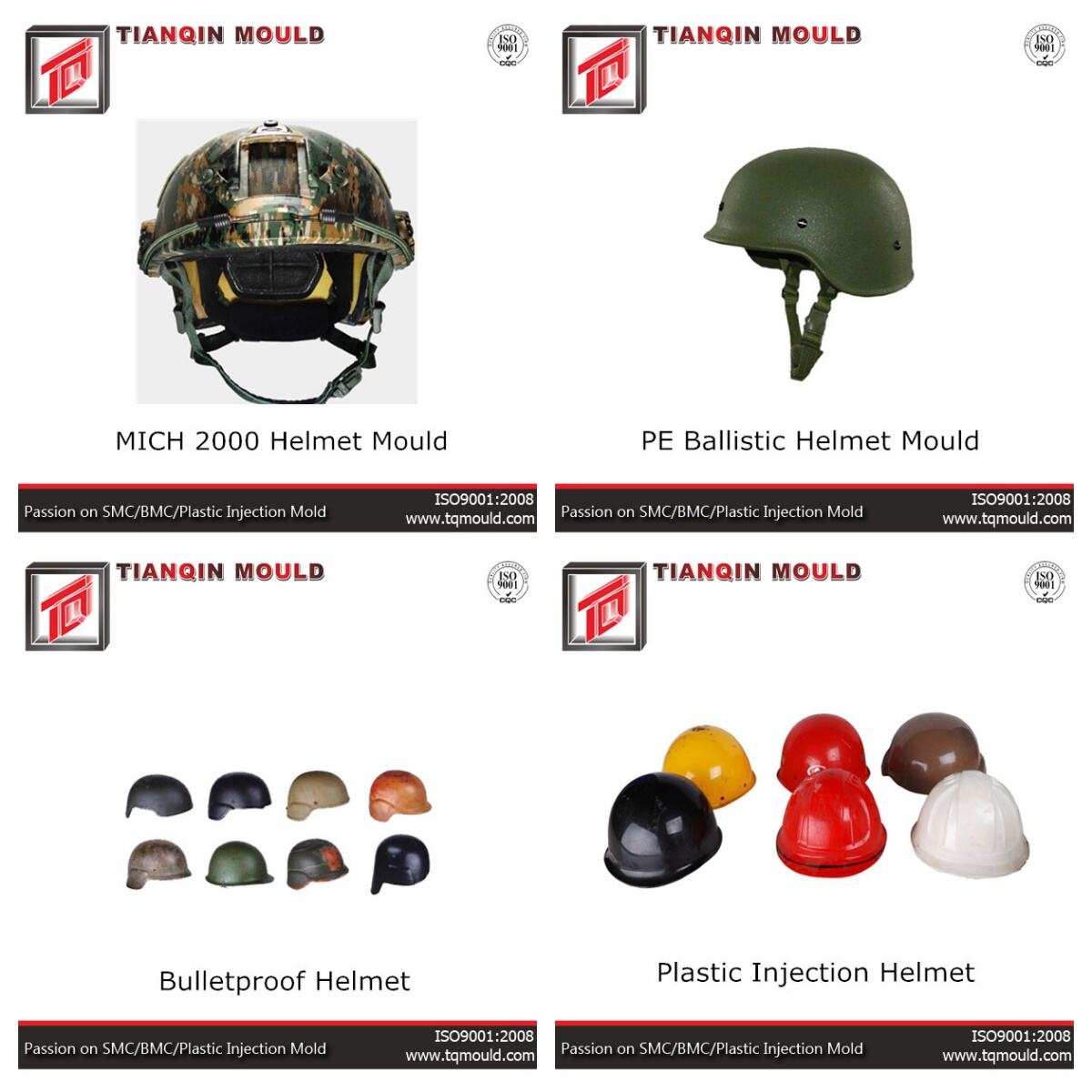

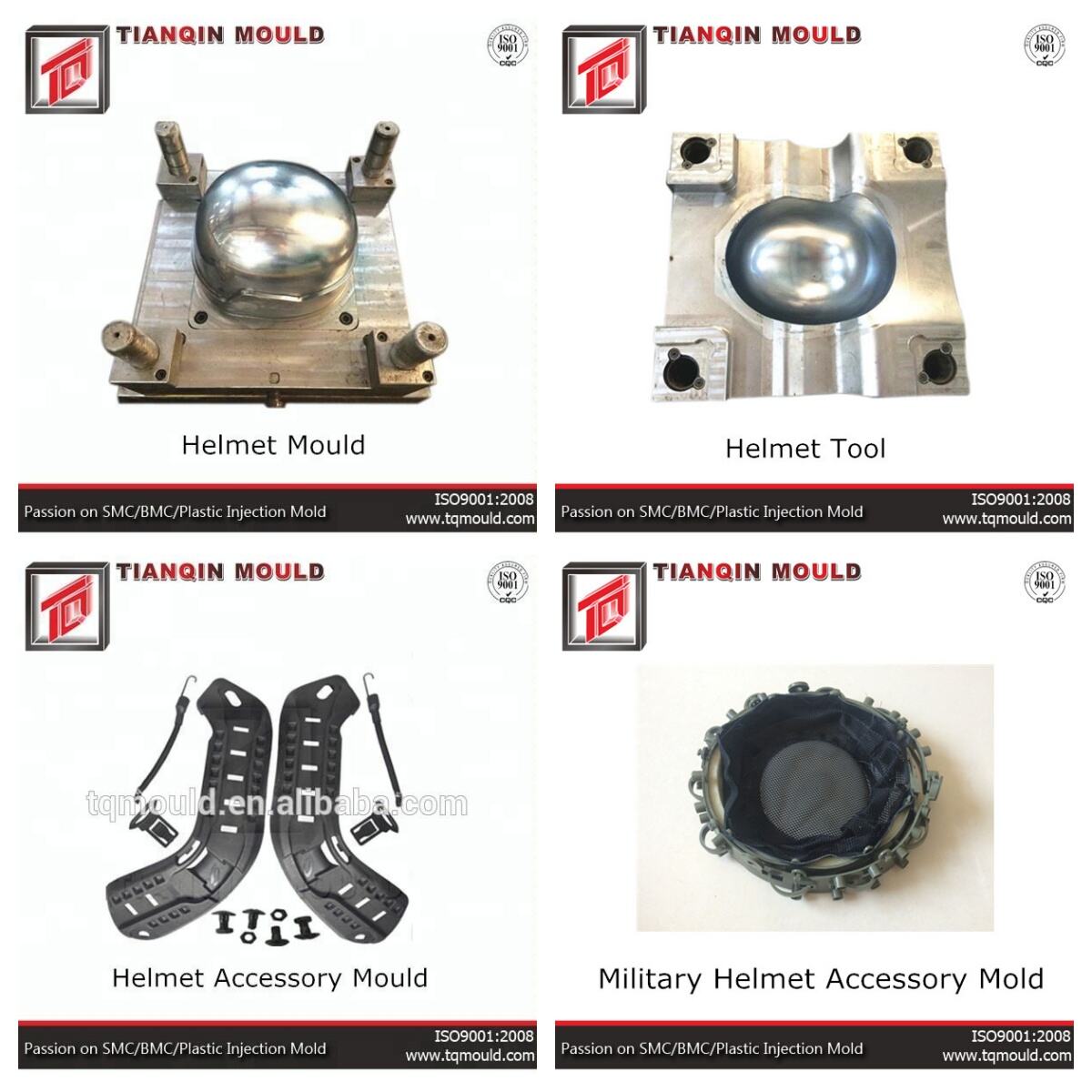

- 5. Products mould: helmet, armor, shield (PE, Kevlar), magazine, etc.

- 6. Other construction & industrial supplies mould: water tank, manhole cover, trash can, dustbin, industrial helmet, etc.

| Name |

Description |

| Mould Material |

45#/ 50# /P20 /H13/ S136 /SKD61/ ect. |

| Cavity |

Single/ Multi |

| Runner |

Cold / Hot |

| Design Software |

UG / CAD / PORE /ect |

| Mould Life |

10,0000 - 1,000,000 shots |

| Delivery Time |

35-50 days |

| Specification |

As the client's requirements |