If people talk about making things, they usually think of tools such as hammers and saws. It is the bricks and mortar, something tangible that those arms can feel in their hands or use to build. But, the other important tools factories of today have to help them produce great things quickly. A plate TQ Moulds is one of these tools that has completely changed the game in how products are manufactured.

A paper plate mold is a where materials are filled in the plate mold and then they cooled down up to fixed shape. Which is important, even if it sounds simple and all of us interact with the things produced by that process every day.

Workers use plate molds at factories for forming different items. It is often used to produce plastic plates, cups and forks. Car parts, toys and medical equipment like syringes or IV bags come in the same molds too. Which is why, plate molds are used to make these day-to-day items of our use.

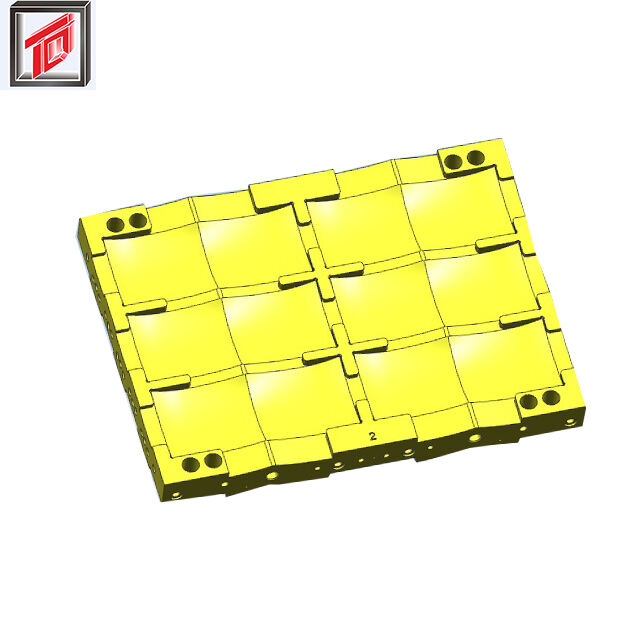

One good thing about plate molds is that they help to produce a large number of units as time-motion study shows. This is most important in the case of enticing and high-demand products. A still faster route is when factories use special machines to output several plate TQ smc mould at once. This is what save their time and money the more they may produce in that less amount of available lesser time.

Plate molds can also be adapted differently so that one is able to obtain multiple and varying designs in terms of size. We, are able to fabricate one-of-a-kind products that do not look like anything else on an assembly line. A factory which makes plastic toys could produce dolls with one TQ Moulds and action figures or cars with another. This flexibility allows factories to chase a diverse customer base and make different products.

There are also many new concepts that have been indicated and plenty more to come as further enhancements in plate mold design takes place, every step needing finer tuning. The greater smc mould are supposed to be effortlessly cleanable which prevents the manufacturer clean. These types are built using hard materials to make them durable that is why you will not have the need of keeping on replacing your mats.

The machines in the factories are generally used with a plate mold. This is the process by which machines do most of the manufacturing but workers check and oversee to make sure everything goes as expected. They have saved us money and time, although they also require a certain level of preparation. In factories, if a product is to be produced then the machines must align and accompanied by appropriate plate Moulds.

TianQin offers plastic products and moulds. There's no limit to the product categories, and the Plate mould for a custom design and custom-designed solutions. Let customers have unique design and highest capacity output.

Tian Qin develops different plans for each project to ensure quality and production as quickly as possible. We will make use of professional equipment prior to delivery to test the Plate mould as well as the structure to ensure that the customer receives the items in perfect order.

The company holds ISO, Plate mould and a variety of other certifications. The warranty duration is 12 months from the date of receipt of the products from the buyer, however we will respond positively to any issues after sales, regardless of the length of 12 months, aiming at solving the concerns of the client.

TianQin's factory has an area of Plate mould. it has its own processing equipment and a team of experts who have worked in the mould industry for more than 20 years. They can provide customers the best solutions.